Then he'll learn not to do it again.

Won't have to tell him twice.....

Then he'll learn not to do it again.

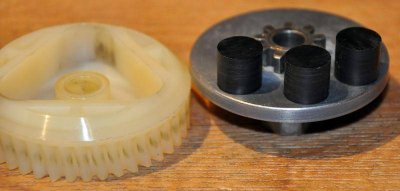

Here's what to buy- hardware store nuts...they are metal, will never fail, and work perfectly (a 7/16 socket fits these in case you're wondering)

theres a fella l know in Idaho that gos this route

brake line and gas line hose...

Is this supposed to be a tight fit with the nuts? I used a metric M7 nut (11mm wrench size, 7/16 nut is 11.1mm) and I have aprox. 5-10mm of play in the gear from stop to stop.

Note: You should be able to grab the gear and hmove it a bit after assembly..as mentioned sixteenth to eighth of an inch play is enough.

I like this solution better than the steel nut one for three reasons. First, the flexible hose acts like a shock absorber when reversing the window direction of travel, i.e. no metal on metal clunk. Secondly, steel nuts being harder than the white metal casing will cause wear and I'd rather replace a worn out the puck than the whole gear housing. Finally, those pictures show the rebuild Paul did on my car, so I've got to love his solution. My windows work perfectly, better in fact than when they were new.

If or when I need to revisit this I'll try the rubber hose version but my nuts are working fine.

LOL oh no... a "Bro-mance" I did the same repair on one of the motors that runs the headlight doors on my Lotus. Now that i see the newer repair I was just thinking that the large diameter hot glue sticks might work instead of the steel nuts... Just cut them to length and bingo good as new! I might t give it a try and let you know.

Damned impressive Julian. I think I might have a man crush...