You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torque straps from Schumacher...

- Thread starter 66SportFury

- Start date

67Monaco

Old Man with a Hat

It's been argued that it was in fact the original. Though I can't see a crimped ring holding the engine, for very long anyway.

It's been argued that it was in fact the original. Though I can't see a crimped ring holding the engine, for very long anyway.

All i can tell ya is our 65 fury has been tore apart for 40 years. I know that mount on the left is not original to the car but the one on the right is. Both were in the trunk when we got it from the father inlaw.

MrMoparCHP

Old Man with a Hat

This is a factory torque strap. Effectiveness?

Alan

This is a factory torque strap. Effectiveness?

Alan

Agreed But its kool that i have one! lol

MrMoparCHP

Old Man with a Hat

Agreed But its kool that i have one! lol

Yup, both my CHP (440) and my Daily Drive Polara (318) have them (both 69's).

Alan

66SportFury

Senior Member

The reason I made the call is that Polylocs are expensive. The other thing is if the engine has a lot of torque then these type Torque Straps in my opinion is the way to go. They won't give you vibration like a solid mount will, but will hold the engine down when launching it hard. The way my 66 is setup,..it looks like it will be straight down from the top bolt (motor mount boss) to the frame. There is a welded in piece of steel on the frame that the bottom of the Torque Strap could mount to.

commando1

Old Man with a Hat

A Heim joint still makes it rigid. A chain or strap still allows the engine to rock n roll.Back in my ignorant youth in the 80s I used a short piece of chain running from an engine bolt to the frame as a "torque strap" when I found out the motor mount on my '70 Sport Satellite 318 was providing a bit more movement than it was supposed to. The chain was functional but it didn't look as cool as a heim joint.

Posted via Topify on Android

MrMoparCHP

Old Man with a Hat

Yeah and the bushings on the bottom allow it to move much like the stock motor mounts. So then, why even bother?

Whereas that may be true, the Schumacher setup has a through bolt, the engine mount splits you have nothing but a dent in the hood and inner fender. It's not the movement you are trying to stop but in the event of a failure not to have the engine move to much.

Alan

67Monaco

Old Man with a Hat

Why would it fail and dent the hood?

MrMoparCHP

Old Man with a Hat

Why would it fail and dent the hood?

That or bend up your aircleaner.

My friends 68 Barracuda has a hole in the inner fender where the exhaust mounting stud pounded through it as a result of a failed mount.

The rotation of the engine will go till something stops it.

That is all these restraints are for, not to protect a mount.

Alan

commando1

Old Man with a Hat

Funny how in 49 years of stomping on it hard I never had an engine mount have a catastrophic failure.

I think these things are more for male enhancement purposes.

If you don't know the signs of an engine mount going bad, turn in your Mopar Card and buy a Chevy.

Posted via Topify on Android

I think these things are more for male enhancement purposes.

If you don't know the signs of an engine mount going bad, turn in your Mopar Card and buy a Chevy.

Posted via Topify on Android

Last edited:

In stock mounts there is nothing connecting the top half of the mount to the bottom except the rubber. If driven only leisurely to church you may never know the rubber has deteriorated, split, or separated from the upper or lower mounting points.

If you 'Launch' it hard you'll find out when the engine torques over and twists the exhaust, breaks an exhaust manifold, damages trans linkage, twists trans lines, etc

As Alan said this the torque strap or locking mounts are insurance but also to eliminate give and transfer the power to the drive line quicker and more efficiently. Similar principal for using traction bars, ladder bars, adjustable pinion snubbers, etc to reduce axle windup

Mitymounts are another locking motor mount and are cheaper thank schumakers

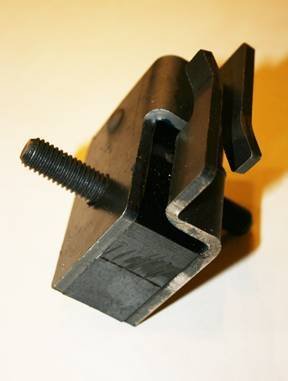

Standard motor mount

mitymount

http://www.mitymounts.com/chrysler.htm

If you 'Launch' it hard you'll find out when the engine torques over and twists the exhaust, breaks an exhaust manifold, damages trans linkage, twists trans lines, etc

As Alan said this the torque strap or locking mounts are insurance but also to eliminate give and transfer the power to the drive line quicker and more efficiently. Similar principal for using traction bars, ladder bars, adjustable pinion snubbers, etc to reduce axle windup

Mitymounts are another locking motor mount and are cheaper thank schumakers

Standard motor mount

mitymount

http://www.mitymounts.com/chrysler.htm

greasemonkeyman

Well-Known Member

Have you possibly tried Steel Rubber Products ? I know they used to do custom vulcanization so maybe they may be able to cast a urethane mount or cast something homemade.

66SportFury

Senior Member

Funny how in 49 years of stomping on it hard I never had an engine mount have a catastrophic failure.

I think these things are more for male enhancement purposes.

If you don't know the signs of an engine mount going bad, turn in your Mopar Card and buy a Chevy.

Posted via Topify on Android

Stan, no offense, but yeah stomping on it hard is one thing when the tires break loose. There isn't that much torque when that happens. BUT, when you are running drag radials or slicks that have been heated and sticky, it's a totally different story. When the tires grab hard, all the torque is on the drive train and not when the tires are spinning/burning out on the street. Plus, I don't want t spend the money on polylocs. I'd rather spend a 1/4 of that and get a strap from them.

66SportFury

Senior Member

Thank you for the link. Much cheaper then Poly's!!!

MrMoparCHP

Old Man with a Hat

67Monaco

Old Man with a Hat

And why wouldn't you want solid mounts in a drag racing application? It's why I asked the question above. No matter how short you make the leash aren't you losing time to rotation?

Similar threads

- Replies

- 35

- Views

- 4K

- Replies

- 3

- Views

- 477

- Replies

- 2

- Views

- 1K