Just HAD it done or just DID it?

LOL! You read it right..........

Just HAD it done or just DID it?

Oh crap! At least it will come apart easier this time.Memo to self:

Mark pieces "L" or "R"" next time...

Memo to self:

Mark pieces "L" or "R"" next time...

Remember Bob we're not all as old as you are!

Yes. Watching you do your two cars...Theres gonna be a next time?

use a tape measure across the tires front and back and get the 2 sides as close as possible

You completely lost me.

Use a tape measure across the tires from where to where?

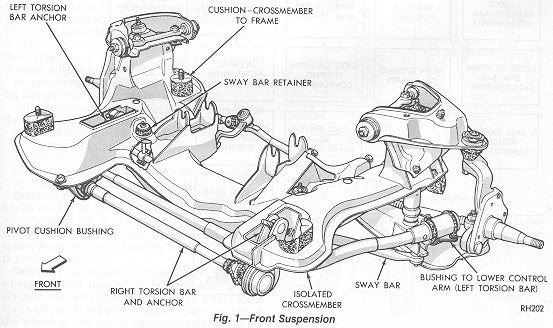

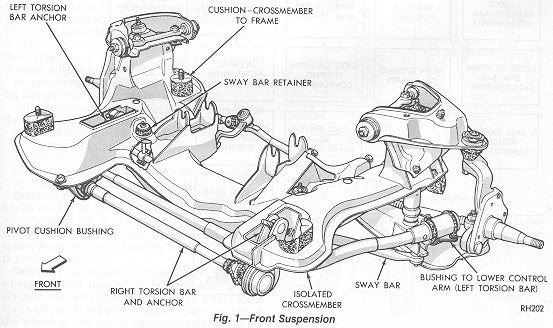

Ignore the torsion bar part:

I plan on FINISHING this job...You should have put me in charge...

Measure across the front and back of the tire to make sure the tierod ends are both adjusted out the same. Ie so one isn't longer than the other. measure from outside edge to outside edge on the tires. You are trying to get the the measurements close.

You should have put me in charge...