Thank you guys!! Appreciate it! Helps keep the motivation going. Hopefully somtime soon I'll finally be able to hear this big block roar to life. I'm getting excited for it! Still have a couple "big" buys to do before hand though.

I left the oil slinger on, Stan. Good/bad?

Today could have gone better, but still got what I wanted done.. Finished cleaning the oil pan, and all the bolts.

My hillbilly bench grinder, to clean the bolts... :uwelcome: Ran outa $$ for more tools!! Ha!

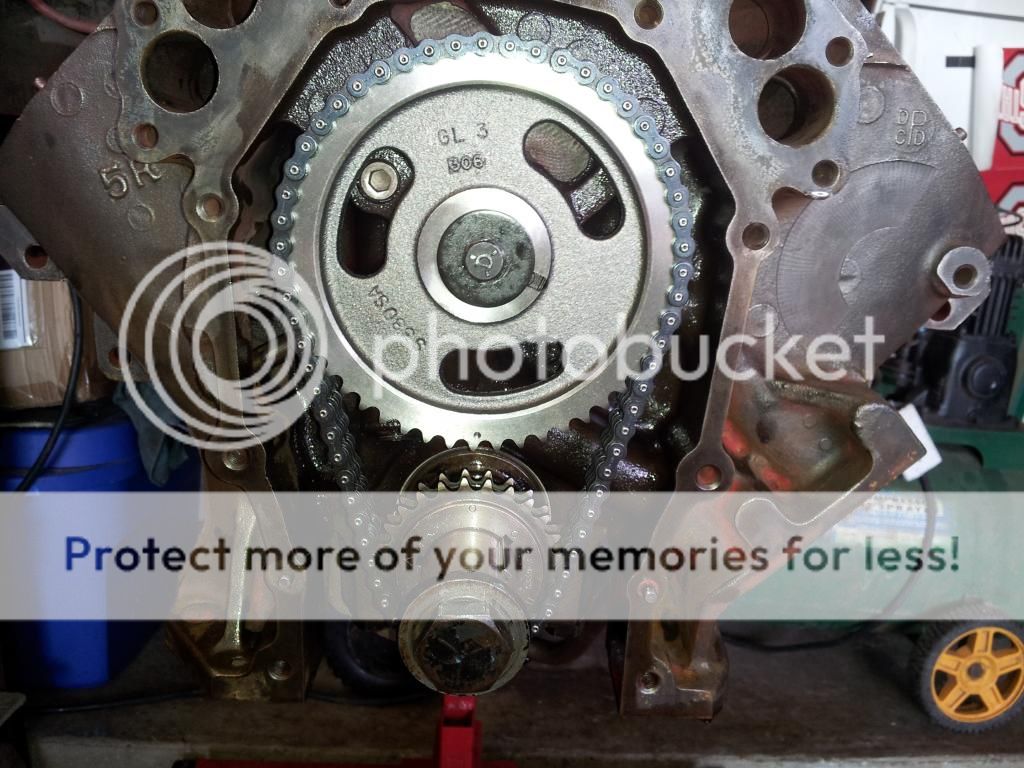

Cleaned and prepped the block

Then the fun came.. Following the instructions in the rebuild book, took the cork oil pan gasket, and put some RTV on it, and placed it on the pan. Then some more RTV, then place on the block. Torque bolts down to 15ft ibs. Well 3/4 the way through, my gasket squished, and tore apart.:icon_hang: Seems like a common occurrence. After looking around on a couple other mopar boards, people say not to use sealant, but adheasive with cork. Also do not torque down, just snug em up. After a trip up to town, and a couple stores finally back with another gasket, and adheasive. Re cleaned the pan, block, and bolts, and installed.

This time I set the torque wrench to 5ft ibs. Didint even make it to that before I noticed the gasket was starting to "squish". Do you guys think I'm alright with this? Its still on there tight, just no where near 15 ft ibs...