newport_66

New Member

Sweding or swaging?

Either way do I need to do it?

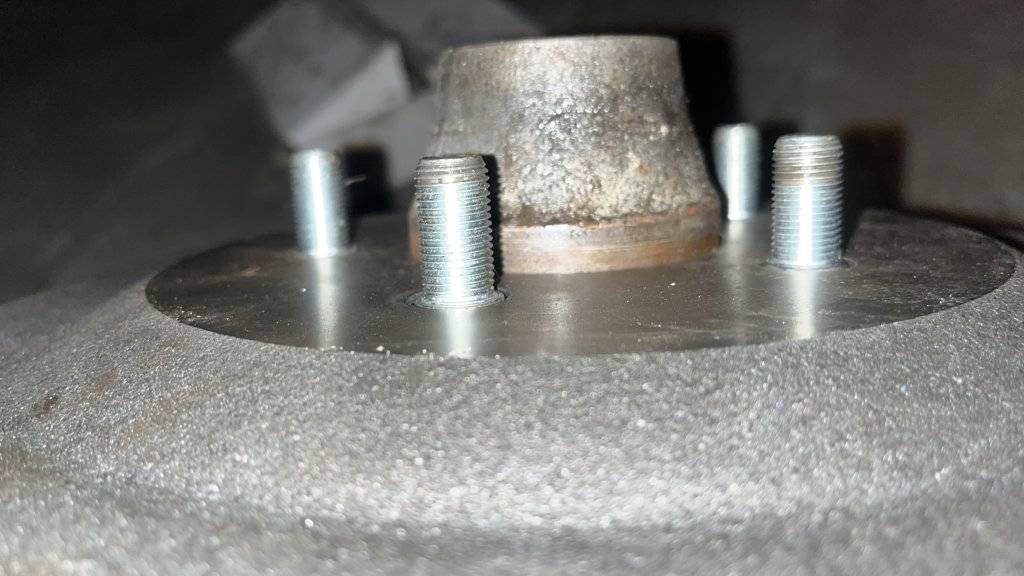

I just got my brake drums and hubs back from a machine shop after 3 months of back and forth. Said they couldn't do it because the smooth part that swages isnt coming out of the drum ... it isnt proud. What a PITA. Not their fault, I verified what theyre saying there is nothing to swedge because the smooth part doesnt come out pass the surface of the drum (see below)

LETS BE CLEAR! I'm asking because im curious not because im considering skipping having the hub swaged. (I suspect the after market crap hubs arent appropriate for the studs that i bought from @mobileparts so ordering the drums and hopefully they will be able to swage the hub to the drum from craig)

So back to the question, when I look at the studs/hub assembly the studs are pressed in and secured by the nurreled part theyre not moving anywhere. The studs slide through the drum holes perfectly. So wondering what would happen if i just put the drum and hub back on the car without swaging. Would the studs rotate when tightening the lugs? The pic below should show that the studs wont rotate the are nurreled part will bite into these edges in the hub. WHY do we need to swedge????

Either way do I need to do it?

I just got my brake drums and hubs back from a machine shop after 3 months of back and forth. Said they couldn't do it because the smooth part that swages isnt coming out of the drum ... it isnt proud. What a PITA. Not their fault, I verified what theyre saying there is nothing to swedge because the smooth part doesnt come out pass the surface of the drum (see below)

LETS BE CLEAR! I'm asking because im curious not because im considering skipping having the hub swaged. (I suspect the after market crap hubs arent appropriate for the studs that i bought from @mobileparts so ordering the drums and hopefully they will be able to swage the hub to the drum from craig)

So back to the question, when I look at the studs/hub assembly the studs are pressed in and secured by the nurreled part theyre not moving anywhere. The studs slide through the drum holes perfectly. So wondering what would happen if i just put the drum and hub back on the car without swaging. Would the studs rotate when tightening the lugs? The pic below should show that the studs wont rotate the are nurreled part will bite into these edges in the hub. WHY do we need to swedge????