FarCanal

Member

Hi Guys

Big Jim from Down Under

You may recognise my (Imported from your Country) 1976 New Yorker Coupe (pic)

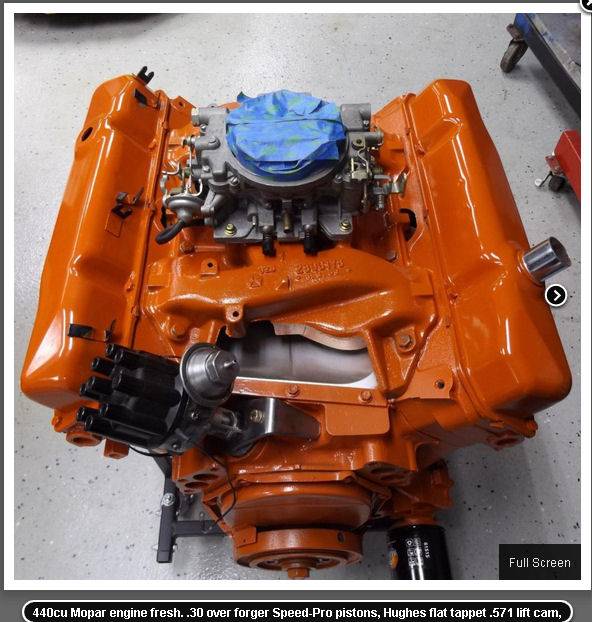

Anywhoooo ..... whilst Importing I bought THIS (pic #2) - got it for $2k = WooHoo

TWO problems

(a) is there a Kit etc available so I can hook / bolt up my A/C (No Nut welded to Block)

(b) Scored the engine from a "Rebuilder" who went broke @ Auction, but something is NOT right = it's minimum idle etc is 13 degrees BTDC = making it try to turn over backwards when starting - this has killed 3 x Starter Motors, and now has destroyed the Ring Gear ! (YES, I know I shouldda looked before now, but once running was quite driveable, plus the 450+ Horses were just so much fun) lol ....Seriously, ya can't NOT set the timing chain incorrectly (a novice could do this), so is it the Oil Drive "SLOT" is NOT set Parallel to the Block Face ..... which would in effect, put the Distributor the equivalent of @ 1 tooth out ? Hoping you get what I'm trying to describe, Coz it's all coming back out of the car to CHECK the whole job ! ($$$ I ain't got)

Eternally grateful for any and all help / diagnosis / Where to find Seller of "Kit" (a) etc

Flying the Flag DownUnder = MOPAR or no Car

Cheers and New Years Greetings

Jim

P.S. Got my FIRST Dodge Phoenix (64) aged 16, been hotting them up & playing with them ever since !!!

Big Jim from Down Under

You may recognise my (Imported from your Country) 1976 New Yorker Coupe (pic)

Anywhoooo ..... whilst Importing I bought THIS (pic #2) - got it for $2k = WooHoo

TWO problems

(a) is there a Kit etc available so I can hook / bolt up my A/C (No Nut welded to Block)

(b) Scored the engine from a "Rebuilder" who went broke @ Auction, but something is NOT right = it's minimum idle etc is 13 degrees BTDC = making it try to turn over backwards when starting - this has killed 3 x Starter Motors, and now has destroyed the Ring Gear ! (YES, I know I shouldda looked before now, but once running was quite driveable, plus the 450+ Horses were just so much fun) lol ....Seriously, ya can't NOT set the timing chain incorrectly (a novice could do this), so is it the Oil Drive "SLOT" is NOT set Parallel to the Block Face ..... which would in effect, put the Distributor the equivalent of @ 1 tooth out ? Hoping you get what I'm trying to describe, Coz it's all coming back out of the car to CHECK the whole job ! ($$$ I ain't got)

Eternally grateful for any and all help / diagnosis / Where to find Seller of "Kit" (a) etc

Flying the Flag DownUnder = MOPAR or no Car

Cheers and New Years Greetings

Jim

P.S. Got my FIRST Dodge Phoenix (64) aged 16, been hotting them up & playing with them ever since !!!