I was more specific on other parts I did already and because the general interest went down a bit, I decided to just post a pictured update of parts I finish now.

But I'm always happy to share my methods and experiences!

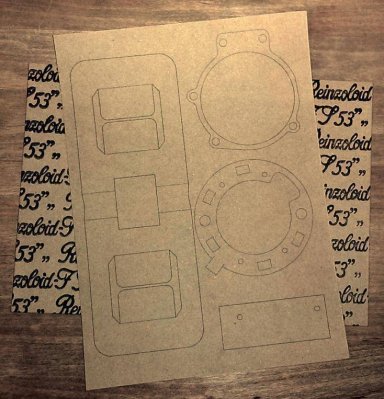

I first start with the tear down and writing a list of parts I will need. After that, I inspect worn and broken parts and think about how to replace them. Most parts I needed until now were not available on the aftermarket. The ones that was, were not fitting proberly...

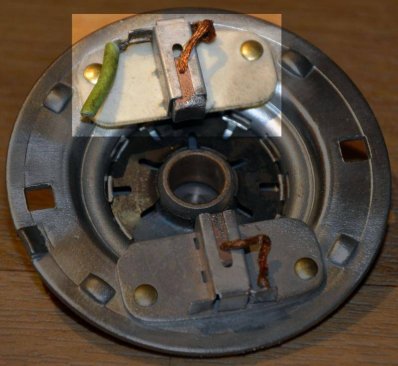

For example on the wiper motor: After tear down, I started with derusting all parts with my bench wire wheel:

Freshly wire wheeled. All rust, dirt and chalk and advesives gone.

Parts like the screws were polished with the polishing disc on the bench grinder and a block of special polishing paste I ordered online here in germany from a guy who makes them by himself. Great stuff.

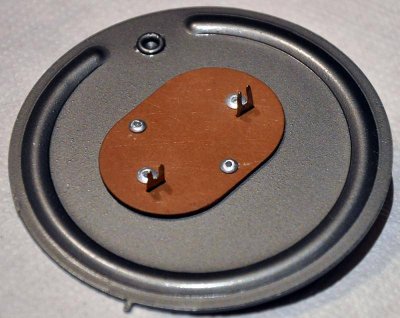

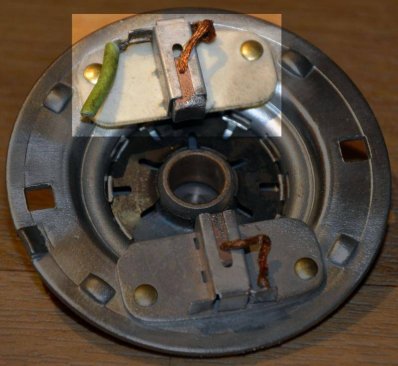

Because the plastic one of the brush mounting plates was brittling away, I made a new one out of FR-4 (circuit board material).

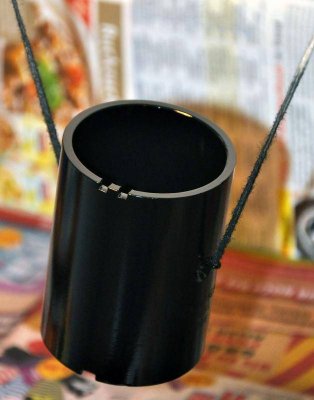

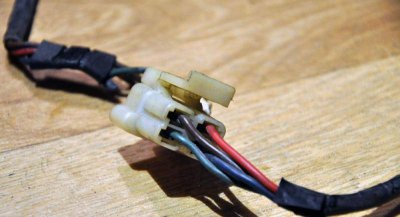

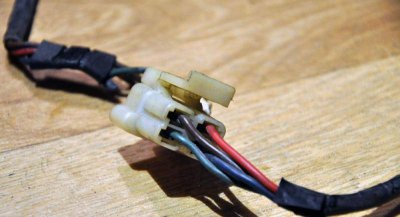

I replaced the old, rotten wires with new ones. That's special automobil approved Oil, fuel and head resistant wires. Regular isolated and cloth jacketed wires for the right look.

I crimped and soldered the new cables to the old terminals. I reused the original terminals, because new ones shipped to germany are expensive and the ones I have are fine. I sanded and polished them to remove all the old deposits and dirt.

...

But I'm always happy to share my methods and experiences!

I first start with the tear down and writing a list of parts I will need. After that, I inspect worn and broken parts and think about how to replace them. Most parts I needed until now were not available on the aftermarket. The ones that was, were not fitting proberly...

For example on the wiper motor: After tear down, I started with derusting all parts with my bench wire wheel:

Freshly wire wheeled. All rust, dirt and chalk and advesives gone.

Parts like the screws were polished with the polishing disc on the bench grinder and a block of special polishing paste I ordered online here in germany from a guy who makes them by himself. Great stuff.

Because the plastic one of the brush mounting plates was brittling away, I made a new one out of FR-4 (circuit board material).

I replaced the old, rotten wires with new ones. That's special automobil approved Oil, fuel and head resistant wires. Regular isolated and cloth jacketed wires for the right look.

I crimped and soldered the new cables to the old terminals. I reused the original terminals, because new ones shipped to germany are expensive and the ones I have are fine. I sanded and polished them to remove all the old deposits and dirt.

...