I think, I need a lesson in electrical engineering... I am totally new to all the electric stuff and I don't understand exaclty how the headlamp door motor works. I bought some equipment to test and diagnose all the electric stuff already.

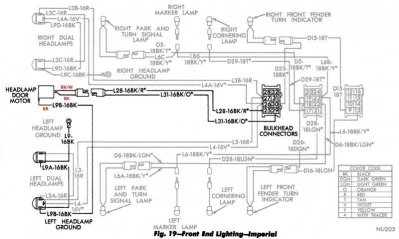

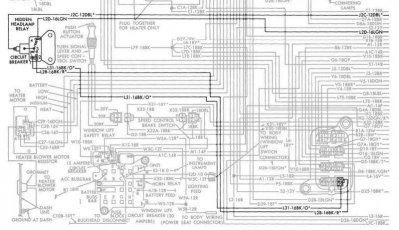

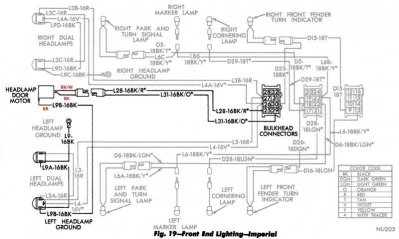

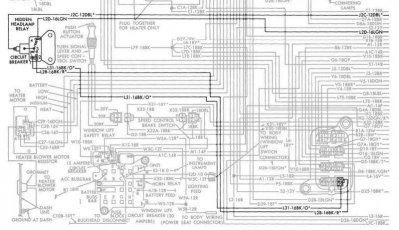

I think my headlamp door motor has a short somewhere and I can't find it... I've read the wiring diagram but now I know less then before...

I already separated the wires of interest.

What I know is, that the brown cable is my ground. The other two cables are going throught the bulkhead into the Hidden headlamp relay. And there, I'm out...

Is the relay directly operated by the headlamp switch in the dashboard to switch current from one cable to the other (BK/W - BK)? If so, there should be no connection between these two cables at any time, right?

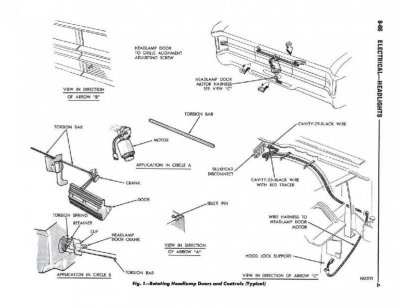

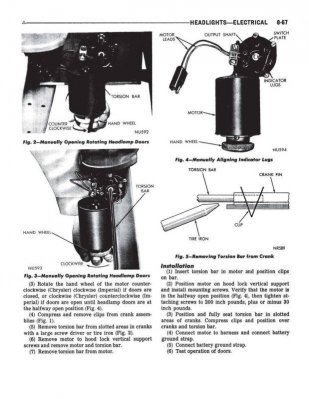

I have a good connection from

Black to

Brown until I turn the motor all to the left until the switch in the motor cover opens up.

I also have a good connection from

Black/White to

Brown until I turn the motor all to the left until the switch in the motor cover opens up.

BUT I also have a connection with more ohms from

Black/White to

Black on the travelway beneath the two cover contacts

. All the way to the left and right is obviously no connection because the shut off switches are open there.

I hope my "descripion" is not too confusing... :O and someone can tell me where my problem is and how to solve it, or even how to measure correctly and what the numbers are meaning.

As I said, I'm a total noob to all the electric stuff but willing to learn in!

p.s. Next to the multimeter, I also bought a power supply to test all the stuff. But my guess, after I saw it in person, is that the 3A it's delivering are way to weak to start this big ol' motors... Is that right or not? How much ampere does such a motor need to start?