bluefury361

Old Man with a Hat

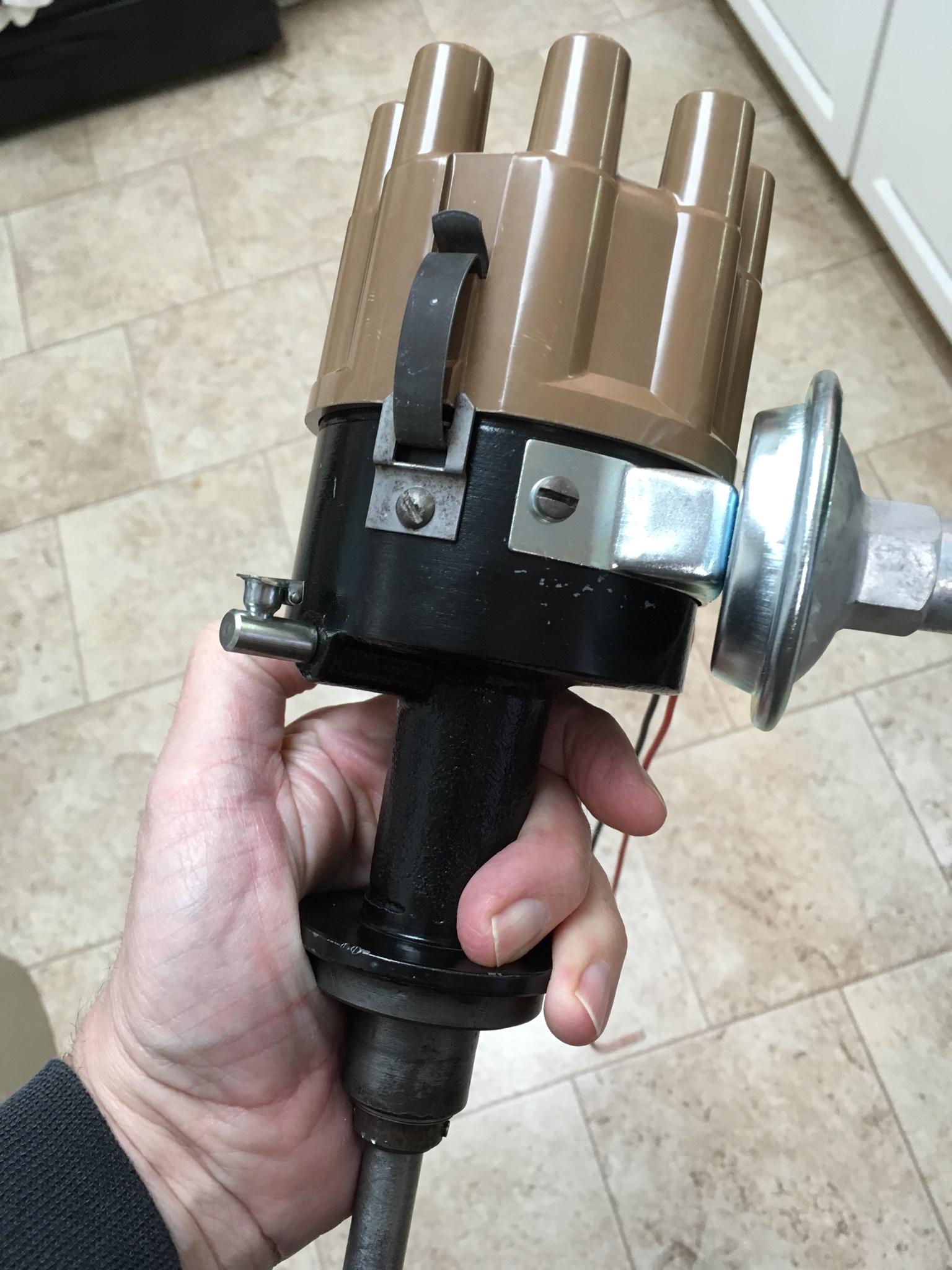

I was trying to figure out why the new dist cap I got from halifaxhops at Carlisle last July wouldn't fit my 67 383. I removed the rotor and took a good look at the dist.... Then had a "WTF" moment. My car has a dual point dist in it. I did not realize that until today.

The shop manual does not cover a dual point in the 383 and no points part numbers in the parts book.

Does anybody recognize this. I need points for it. And apparently the caps are different, need one of those too. I'm not ready to pull it out and look for numbers yet, that time is coming.

The shop manual does not cover a dual point in the 383 and no points part numbers in the parts book.

Does anybody recognize this. I need points for it. And apparently the caps are different, need one of those too. I'm not ready to pull it out and look for numbers yet, that time is coming.

Last edited: