I had a little time to sit and look through the bushing spec list for a close bushing that might work for 73 Imperials.

On the spec sheet I found that the BR67/ K7007 is very close in spec to the Imperial BR107/ K7043.

I did a search for the bushing and found that it is for 65 to 73 Chrysler C-bodies. Great, I thought. But on the Rock Auto part information it list the specs of bushing different than the specs on the Moog spec sheet. Would any of you have any experience or bushings on hand to measure? I have just started getting into the C body suspension work in the last few years, so not much inventory for comparing parts here. I have plenty of A, B, and E Body suspension parts and bushings, but no C Body. Getting parts for C bodies and Imperials is much harder to do, but I am into it now with My Imperial and now some clients are buying Cs and Imperials. Plus all the cars that are in the online forums like my Favourite FCBO site. It would be great to find a source for these bushings, as I bet 75% of the cars we own need bushings. Almost every Mopar that I have worked on needed lower control arm bushings.

Thanks.

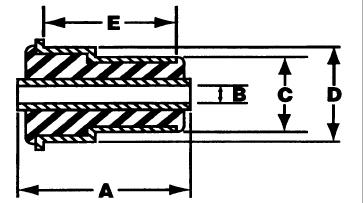

Here are the specs from Moog page.

73 Imperial:

BR107

K7043

A. 2.234

B. 0.875

C/D. 1.766

E. 2.234

67-73 C-Body bushing.

BR67

K7007

A. 2.297

B. 0.844

C/D. 1.734

E. 2.297

Rock Auto spec sheet.

Link to complete Moog bushing specs. https://www.pirate4x4.com/d1/tech/billavista/PDFs/Moog_rubber_bushing_cross_reference.pdf

Jackson Boyd from Jackson's

On the spec sheet I found that the BR67/ K7007 is very close in spec to the Imperial BR107/ K7043.

I did a search for the bushing and found that it is for 65 to 73 Chrysler C-bodies. Great, I thought. But on the Rock Auto part information it list the specs of bushing different than the specs on the Moog spec sheet. Would any of you have any experience or bushings on hand to measure? I have just started getting into the C body suspension work in the last few years, so not much inventory for comparing parts here. I have plenty of A, B, and E Body suspension parts and bushings, but no C Body. Getting parts for C bodies and Imperials is much harder to do, but I am into it now with My Imperial and now some clients are buying Cs and Imperials. Plus all the cars that are in the online forums like my Favourite FCBO site. It would be great to find a source for these bushings, as I bet 75% of the cars we own need bushings. Almost every Mopar that I have worked on needed lower control arm bushings.

Thanks.

Here are the specs from Moog page.

73 Imperial:

BR107

K7043

A. 2.234

B. 0.875

C/D. 1.766

E. 2.234

67-73 C-Body bushing.

BR67

K7007

A. 2.297

B. 0.844

C/D. 1.734

E. 2.297

Rock Auto spec sheet.

|

Jackson Boyd from Jackson's

Last edited: